The application of hard carbon in the field of lithium-ion batteries

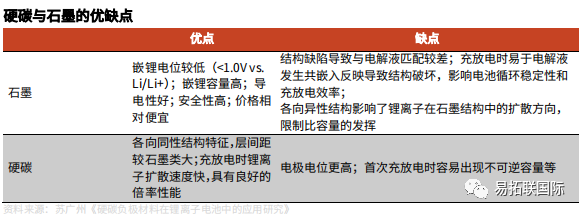

At present, most domestic enterprises that layout hard carbon have applied it to lithium-ion batteries and have achieved rich results and practices. In the selection of negative electrode materials for lithium-ion batteries, graphite has become the main raw material. The graphite anode has structural defects that limit its cycle stability and charge discharge efficiency as the anode material of lithium ion batteries. Hard carbon has isotropic structural characteristics, larger layer spacing, and good rate performance due to rapid lithium ion diffusion during charge and discharge, which makes hard carbon have a good application in the field of lithium ion batteries.

As mentioned above, hard carbon is an important negative electrode material for Sodium-ion battery. Its excellent specific capacity and low price are important advantages that it stands out from many negative electrode materials. The lithium-ion battery, also known as the "rocking chair battery", can actually use hard carbon as its negative electrode raw material due to its high similarity to the principle of sodium batteries. In the negative electrode materials of lithium-ion batteries, natural graphite and artificial graphite have always accounted for the vast majority. However, with the increasing demand for battery energy density in the future, the theoretical upper limit of 372mah/g of graphite specific capacity will no longer meet the demand. At that time, silicon negative electrode materials and hard carbon materials that can also achieve higher specific capacity will have a greater performance stage. At present, silicon negative electrode materials have not yet achieved all battery applications, but hard carbon materials have already taken up a certain proportion in lithium battery negative electrode materials.

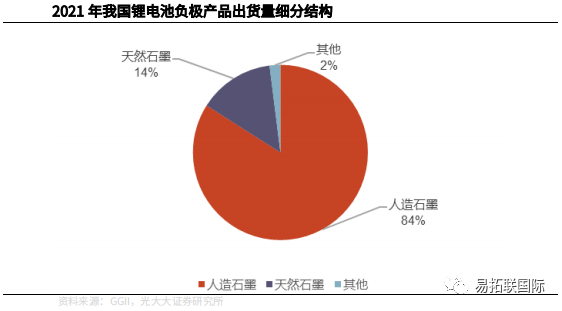

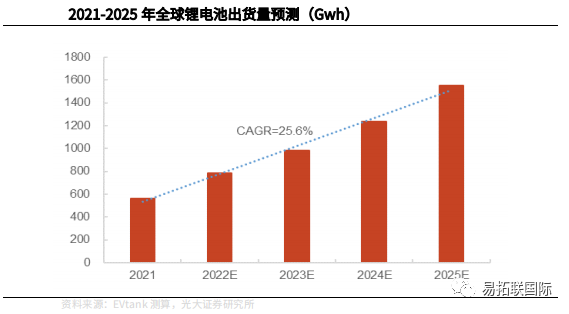

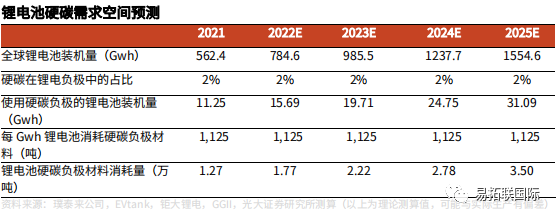

In 2021, the shipment volume structure of lithium battery negative electrode products in China will still be dominated by artificial graphite, accounting for 84%; Natural graphite is the second largest segmented negative electrode product, accounting for 14%; The remaining negative electrode materials are 2%. In other parts, hard carbon and soft carbon materials are the main components. According to the data of Giant Lithium Battery, in the global shipment of lithium battery negative electrode materials in 2015, soft carbon and hard carbon materials accounted for 1.7%. In recent years, the application of hard carbon materials in lithium batteries has also made some industrial progress. Therefore, we predict that in the next few years, hard carbon materials will be a Applied Materials of lithium battery cathode, accounting for about 2%. The future shipment volume of lithium batteries is showing a trend of increasing. With the continuous improvement of the global penetration rate of new energy vehicles and the gradual advancement of the dual carbon goal, the demand for power batteries and energy storage batteries will continue to grow at a high speed. Before 2030, other battery systems will still be difficult to develop in large-scale industrialization, and lithium-ion batteries will still be the mainstream Technology roadmap. EVTank predicts that the annual compound growth rate of global lithium-ion battery shipments will reach 25.6% before 2030. In 2021, the global shipment volume of lithium batteries reached 562.4Gwh. Based on the compound growth rate of this year, it is estimated that the global shipment volume of lithium batteries will reach around 1554.6Gwh by 2025.

Due to the low proportion of hard carbon in the negative electrode material of lithium batteries, lithium batteries will have a smaller pull on hard carbon materials. If calculated based on a capacity of 300mah/g of hard carbon and a 3.2V voltage platform, 1GWh lithium batteries consume approximately 1125 tons of hard carbon. We predict that by 2025, approximately 35000 tons of hard carbon materials will be used for the production of negative electrode materials for lithium batteries.

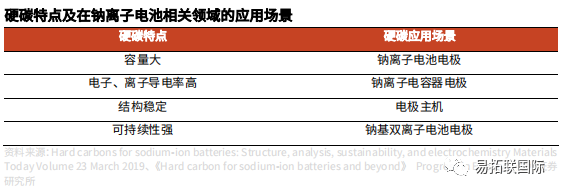

Characteristics of hard carbon and its application scenario in Sodium-ion battery

Recently, when testing the electrochemical performance of hard carbon material, the research team found that when it was used as the anode material of Sodium-ion battery, a sample showed a high specific capacity of 369.8mAh/g; The research group of Zhouguang in Southern Kedali found that hard carbon has a low oxidation Reduction potential (0.1-1.0V). Due to the widespread use of hard carbon precursor biomass related precursors, hard carbon has also become a green and environmentally friendly choice for battery negative electrode materials. To sum up, in the application field of Sodium-ion battery, hard carbon has a larger spacing than graphite and can form thermally stable intercalation compounds with sodium, and has a larger sodium storage capacity than soft carbon. It has good application scenarios in Sodium-ion battery electrodes, sodium ion capacitor electrodes, sodium based double ion battery electrodes and other Sodium-ion battery related fields. At present, it has also been studied and put into application by Beiteri, Shanshan New Energy and other companies.

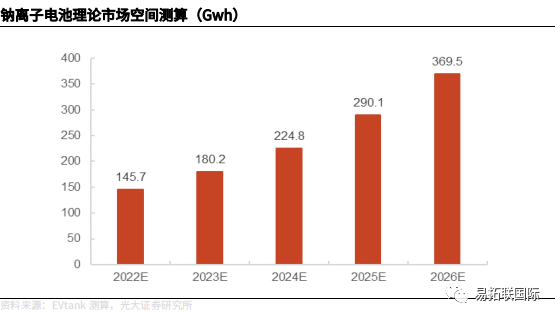

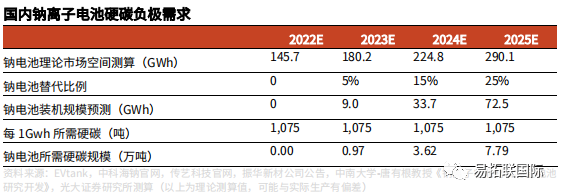

In the White Paper on the Development of China's Sodium-ion battery Industry (2022) jointly released by EVTank and Ivey Economic Research Institute, after a comprehensive comparative analysis of the characteristics of Sodium-ion battery, Lithium iron phosphate battery, ternary battery and lead-acid battery in terms of energy density, cycle life, average voltage, safety, rate performance and fast charge performance, high and low temperature performance, it is believed that Sodium-ion battery can be used in electric two wheeled vehicles, Neighborhood Electric Vehicle Application scenarios such as energy storage and start stop have good prospects. EVtank believes that theoretically, the market space of Sodium-ion battery can reach 369.5GWh in 2026 with 100% penetration, and its theoretical market scale may reach 150 billion yuan.

Assuming that the replacement ratios of sodium batteries from 2023 to 2025 are 5%, 15%, and 25% respectively, the corresponding installed capacity of sodium batteries is 9GWh, 33.7GWh, and 72.5GWh. If calculated based on a hard carbon capacity of 300mah/g and a 3.4V voltage platform, 1GWh sodium batteries consume approximately 1075 tons of hard carbon. We estimate that the corresponding hard carbon demand for sodium batteries from 2023 to 2025 will be 9700 tons, 36200 tons, and 77900 tons.

Summarizing the two parts of hard carbon demand, we estimate that the total demand for hard carbon in 2021 will be approximately 12700 tons, while the total demand for hard carbon in 2025 is expected to significantly increase to around 112900 tons, with a compound annual growth rate of 72.8%.

Phone:+86 13861313805

Phone:+86 13861313805

E-mail:louis.han@e-tygroup.com

E-mail:louis.han@e-tygroup.com

Add:Room 2809, Building Ⅱ, The Gate of the Orient, No. 199 Xinggang Street, Suzhou Industrial Park, Suzhou, China.

Add:Room 2809, Building Ⅱ, The Gate of the Orient, No. 199 Xinggang Street, Suzhou Industrial Park, Suzhou, China.