The composition and principle of activated carbon were briefly introduced in the previous text. Next, we will continue to explain the characteristics, classification, and technical indicators of activated carbon. Take everyone to understand activated carbon!

1.1、Adsorption characteristics

Activated carbon adsorption method is a method of using porous activated carbon to remove one or more substances from water by adsorbing them on the surface of activated carbon. The removal objects include dissolved organic substances, synthetic detergents, microorganisms, viruses, and a certain amount of heavy metals, and can also decolorize, deodorize, purify air, and treat water.

Activated carbon, sulfonated coal, zeolite, coke, and other commonly used adsorbents for water treatment. After activation, activated carbon forms well-developed pores with varying shapes and sizes in the carbon lattice, greatly increasing the specific surface area and improving adsorption capacity. The Galaxy effective radius of pores of activated carbon is generally 1-10000nm, the radius of pores is below 2nm, the radius of transition pores is generally 2-100nm, and the radius of macropores is 100-10000nm. The volume of small pores is generally 0.15-0.90mL/g, and the area of transition pores is generally 0.02-0.10mL/g; The volume of large pores is generally 0.2-0.5mL/g.

Activated carbon is a type of very small carbon particle with a large surface area, and there are even smaller pores in the carbon particle - capillaries. This type of capillary has strong adsorption capacity, and due to the large surface area of carbon particles, it can fully come into contact with gases (impurities). When these gases (impurities) touch the capillary tube, they are adsorbed and play a Catharsis role.

Activated carbon can effectively adsorb chlorinated hydrocarbons, organic phosphorus and carbamate pesticides, as well as phenyl ether, n-nitrochlorobenzene, naphthalene, ethylene, alkylbenzene sulfonic acid and many ester and aromatic compounds. The secondary effluent also contains organic substances that are not adsorbed by activated carbon, such as intermediate degradation substances of proteins, which are more difficult to be adsorbed by activated carbon than the original organic substances. The removal capacity of activated carbon for THMS is relatively low, only reaching 23-60%. The combination of activated carbon adsorption method and other treatment methods has led to the emergence of ozone activated carbon method, coagulation adsorption activated carbon method, etc., which significantly prolongs the adsorption cycle of activated carbon, reduces the dosage, and greatly improves the treatment effect and scope.

1.2、chemical PROPERTIES

The adsorption of activated carbon not only involves physical adsorption, but also chemical adsorption. The adsorption capacity of activated carbon depends on both pore structure and chemical composition.

Activated carbon not only contains carbon, but also a small amount of chemically bound and functional oxygen and hydrogen, such as carbonyls, carboxyls, phenols, lactones, quinones, and ethers. The oxides and complexes contained on these surfaces, some of which come from derivatives of raw materials, and some are generated by the action of air or water vapor during or after activation. Sometimes surface sulfides and chlorides are also generated. During activation, the minerals contained in the raw materials are concentrated in activated carbon to form ash, which is mainly composed of salts of alkali metals and alkali earth metals, such as carbonates and phosphates.

1.3、mechanical properties

1. Particle size: a set of standard sieve screening method is used to calculate the weight of activated carbon left in and passed through each sieve, which represents the particle size distribution.

2. Static density or bulk density: should be the weight of activated carbon per unit volume of pore volume and interstitial volume between particles.

3. Volume density and particle density: should be the weight of activated carbon per unit volume of pore volume rather than the volume of voids between particles.

4. Strength: refers to the crushing resistance of activated carbon.

5. Wear resistance: refers to the ability to resist wear or friction.

These mechanical properties directly affect the application of activated carbon, such as density affecting container size; The fineness of powdered carbon affects filtration; The particle size distribution of granular carbon affects fluid resistance and pressure drop; Fragmentation affects the service life of activated carbon and the regeneration of waste carbon.

2.1、By source of raw materials:

1. Wood activated carbon

2. Mineral raw material activated carbon

3. Regenerated activated carbon

4. Activated carbon from other raw materials

2.2、 Classified by manufacturing method:

1. Chemical activated carbon (chemical carbon)

2. Physical activated carbon (physical carbon)

3. Chemical physical method or physical chemical method activated carbon

2.3、Divided by appearance and shape:

1. Powdered activated carbon

2. Granular activated carbon

3. Unshaped granular activated carbon

4. Cylindrical activated carbon

5. Spherical activated carbon

6. Other shapes of activated carbon

2.4、Divided by aperture:

Large hole: aperture>1000A °

Transition hole: aperture 20~1000A °

Micropores: The surface area of activated carbon with a pore size<20A ° is mainly provided by micropores

2.5、Classification by Material:

1. Type: Raw materials

2. Wood activated carbon: Activated carbon made from wood chips, charcoal, etc

3. Fruit shell activated carbon: Activated carbon made from coconut shell, walnut shell, apricot kernel shell, etc

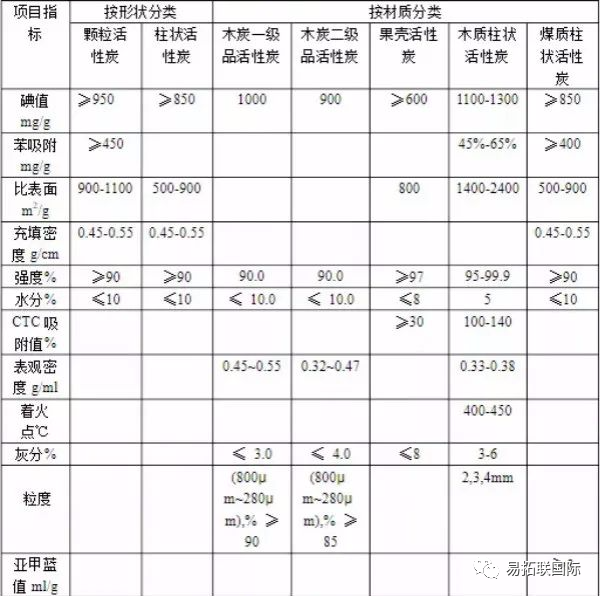

3.1、Technical indicators of activated carbon

Note: Using high-quality charcoal and sawdust as raw materials, it is refined by physical and chemical methods. The product is in black powder form, non-toxic and odorless, with well-developed pores, and does not contain dissolved substances in water that have adverse effects on water quality. It has advantages such as strong adsorption capacity, good decolorization effect, and fast filtration speed. It can effectively adsorb large and small molecular structure undesirable substances in the liquid phase, and is widely used in domestic sewage, chemical sewage, medical sewage, urban sewage and other types of sewage, especially for decolorization, deodorization, COD reduction, etc.

A good activated carbon must have characteristics such as large adsorption capacity, long service life, high mechanical strength, low ash content, easy flushing, and good effluent quality. It can not only remove odors and odors, improve color, but also has a high removal rate for various toxic and harmful substances in water, such as chlorine, phenol, mercury, lead, arsenic, chloride, detergent, pesticide, fertilizer, and other pollutants.

The main technical indicators are as follows:

1. Particle size (10-24 mesh 2.0-0.8mm): ≥ 95%

Explanation: Generally speaking, the smaller the particle size of activated carbon, the larger the specific surface area, which means the better the adsorption effect. However, the smaller the particle size, the greater the loss and the more dust.

2. Iodine adsorption value: ≥ 1000mg/g

Explanation: Generally speaking, the higher the iodine adsorption value, the stronger the adsorption capacity of activated carbon.

3. Specific surface area: 1000-1200 ㎡/g

Explanation: If 1 gram of activated carbon is taken and all the pore walls inside are unfolded into a plane, this area will reach 1000 square meters (i.e. a specific surface area of 1000 square meters/g)! The main factor affecting the adsorption capacity of activated carbon depends on the degree of development of its internal pore structure. The larger the specific surface area, the better the adsorption effect of activated carbon.

4. Methylene blue decolorization power: ≥ 10ml/g

Description: Color removal ability.

5. Wear resistance: ≥ 95%

Explanation: It refers to the performance of wear resistance or friction resistance; The higher the strength, the better the performance of activated carbon.

6. Drying reduction: ≤ 10%

Explanation: Drying reduction refers to moisture content. The lower this value, the better the quality of activated carbon.

7. Burning residue: ≤ 3%

Explanation: The lower the ignition residue and ash content, the better the quality of activated carbon.

8. Filling specific gravity: 0.48-0.55g/ml

Explanation: The filling density and specific gravity refer to the density. Generally, the smaller the density, the better the adsorption capacity of activated carbon.

9. PH value: 6-8

Phone:+86 13861313805

Phone:+86 13861313805

E-mail:louis.han@e-tygroup.com

E-mail:louis.han@e-tygroup.com

Add:Room 2809, Building Ⅱ, The Gate of the Orient, No. 199 Xinggang Street, Suzhou Industrial Park, Suzhou, China.

Add:Room 2809, Building Ⅱ, The Gate of the Orient, No. 199 Xinggang Street, Suzhou Industrial Park, Suzhou, China.