PREFACE

In recent years, with the widespread application of activated carbon, people have gained some understanding of the various indicators and parameters of activated carbon. However, relatively speaking, the well-known indicators of activated carbon are limited to iodine adsorption value, and the understanding of ash content in many customers is not thorough enough. So let's carefully explore the impact of ash on the preparation, pore structure, and electrochemical performance of activated carbon.

Activated Carbon Preparation Equipment for Suzhou Yituolian International Trade Co., Ltd. Jakarta Factory, Indonesia

The Effect of Ash on the Preparation Process of Activated Carbon

Ash content refers to the inorganic components in activated carbon, mainly including K ₂ O, Na ₂ O, CaO, MgO, Fe ₂ O Å, Al ₂ O Å, P ₂ O Å, SO Å, Cl - and other components.

The basic principle of activation is that the activator reacts with carbon atoms, consuming them to generate volatile gases, thereby developing pore structures.

During the entire activation process, ash has little beneficial effect, and all ash in the raw material will be transferred into activated carbon, reducing the fixed carbon content and affecting the adsorption performance of activated carbon.

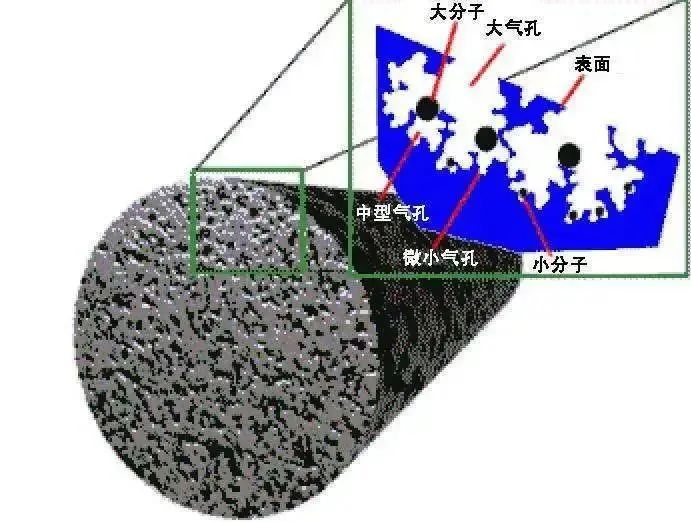

Pore structure diagram of activated carbon

The Effect of Ash on the Pore Structure of Activated Carbon

The presence of ash in activated carbon blocks some of the pores, while the removal of ash can form new pores, especially micropores.

When using water vapor as an activator, if the ash content of the raw material is high, the resulting activated carbon will have larger pores, more mesopores, and slightly lower specific surface area. The preparation process of activated carbon is generally divided into three stages:

During the opening stage, a large number of micropores are generated;

During the expansion stage, a large number of mesopores are generated;

Create a new pore stage, generating large pores and new micropores.

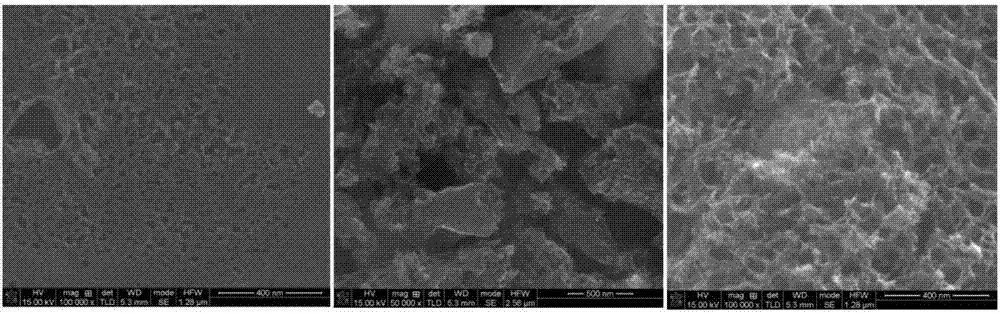

Double layer of activated carbon under a microscope

The Effect of Ash Content on the Electrochemical Performance of Activated Carbon

Ash content is an important reason for the poor electrochemical performance and low stability of supercapacitors.

Ash content promotes the diffusion of ions from the double layer to the solution, accelerates the disintegration of the double layer, increases leakage current and self discharge, and reduces the stability of the double layer.

The presence of ash will reduce the capacitance and rate characteristics of activated carbon.

The surface hydrophilicity of low ash activated carbon is stronger than that of high ash activated carbon, which can promote the formation of double electric layers.

Suzhou Yituolian International Trade Co., Ltd. Activated carbon deashing equipment at the Surabaya factory in Indonesia

Selection of timing for activated carbon deashing

One of the fundamental ways to improve the quality of activated carbon is to choose the appropriate timing for economic and effective deep deashing of activated carbon. Activated carbon deashing mainly occurs in three stages: early, middle, and late stages. Pre ash removal refers to the removal of ash from raw materials before the preparation of activated carbon, but with a large amount of treatment. Medium term deashing can complicate the preparation process of activated carbon, so it is rarely used. Post ash removal is a process of ash removal after the preparation of activated carbon, and it is also the most widely used method of ash removal.

In summary, the selection of the timing for ash removal needs to consider multiple factors such as the characteristics of the raw materials themselves, the preparation process, and the use of activated carbon.

Conclusion

In the process of preparing activated carbon, the presence of ash will lead to an increase in the required activator, an extension of time, and a corresponding higher temperature. Ash can hinder the contact between activator and carbon atoms, inhibit activation, and affect the development and changes of pores.

To obtain ultra pure activated carbon, it is necessary to consider various factors such as raw materials, preparation process, and usage, and choose the appropriate timing and method for ash removal. Under the premise of ensuring sufficient activation, saving the amount of activator and obtaining activated carbon with larger pore size, early deashing can be chosen; When the ash content of the raw material is low and difficult to remove, and it is desired to obtain activated carbon with smaller pore size, late deashing can be considered.

Phone:+86 13861313805

Phone:+86 13861313805

E-mail:louis.han@e-tygroup.com

E-mail:louis.han@e-tygroup.com

Add:Room 2809, Building Ⅱ, The Gate of the Orient, No. 199 Xinggang Street, Suzhou Industrial Park, Suzhou, China.

Add:Room 2809, Building Ⅱ, The Gate of the Orient, No. 199 Xinggang Street, Suzhou Industrial Park, Suzhou, China.